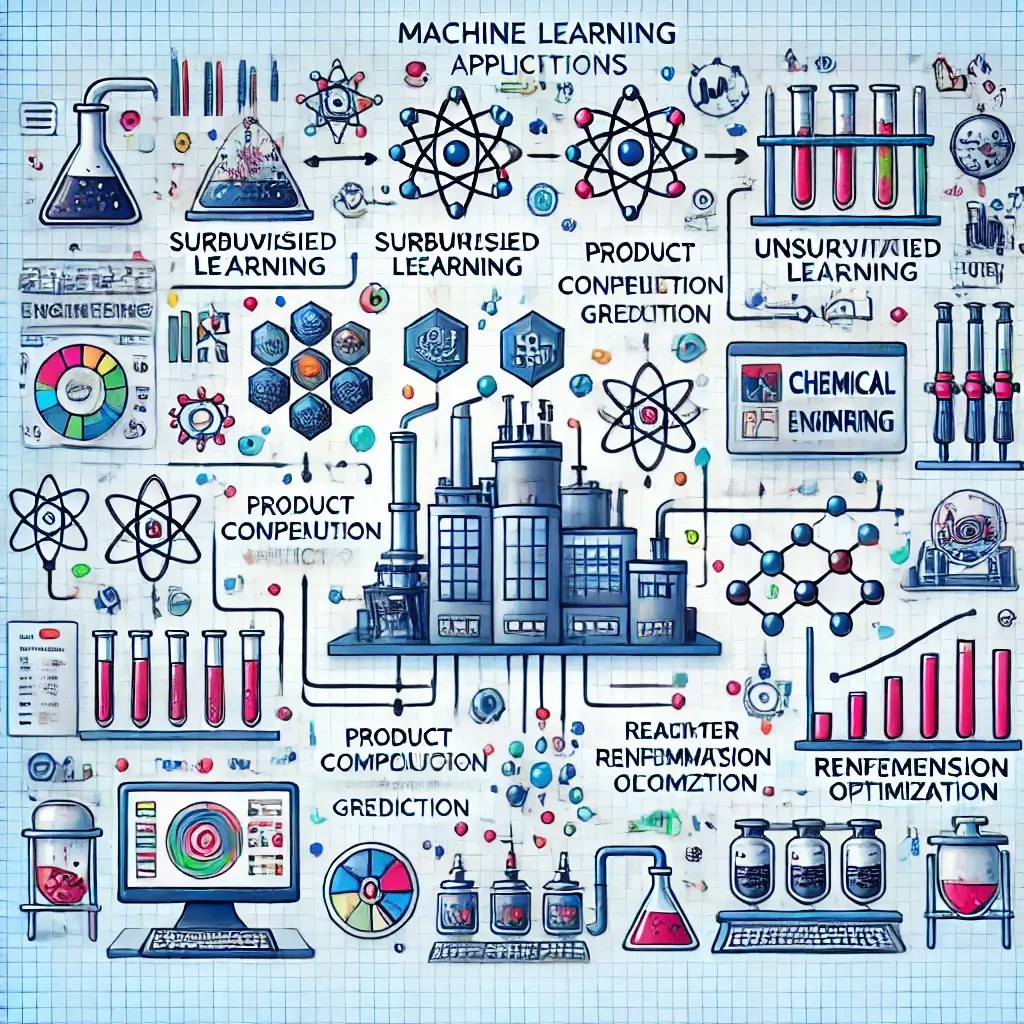

Machine Learning in Chemical Engineering has become a vital tool in recent years. It aids in everything from process optimization to predictive maintenance. At its core, machine learning allows systems to learn from data. This learning makes it possible to solve complex engineering challenges by identifying patterns and relationships. This article explains three main types of machine learning. These include supervised, unsupervised, and reinforcement learning. The article uses examples from chemical engineering to clarify each concept.

What is Machine Learning?

Machine Learning (ML) is a branch of artificial intelligence. In ML, computers learn patterns from data. They make decisions or predictions without explicit programming for each specific task.

Think of ML as teaching a computer to “understand” patterns—just like we learn from experience, the computer learns from data.

Types of Machine Learning in Chemical Engineering

In Machine Learning for Chemical Engineering, there are mainly three types:

- Supervised Learning

- Unsupervised Learning

- Reinforcement Learning

Supervised Learning

In supervised learning, we train the model using a labeled dataset. This means we have both the input data (features) and the correct output (target) for each data point. The model learns the relationship between inputs and outputs, allowing it to make predictions on new, unseen data.

Examples of Supervised Learning

1. Predicting Product Concentration

In a chemical process, predicting the final concentration of a product is crucial. This prediction is based on input variables like temperature, pressure, and initial reactant concentration. We use supervised learning to train a model on historical data. This data includes both these input features and the resulting concentration. With enough training, the model learns the relationship between these variables. It then uses this understanding to predict concentration levels accurately for new process conditions.

2. Corrosion Rate Prediction

Corrosion prediction is another area where supervised learning is effective. By feeding the model data on environmental factors (e.g. humidity, pH, temperature) along with the corresponding corrosion rate for various materials, it learns to predict corrosion rates under new environmental conditions.

Supervised learning is ideal for Machine Learning applications in chemical engineering where labeled data exists. It allows engineers to predict specific outcomes based on known inputs.

Unsupervised Learning

In unsupervised learning, the model works with unlabeled data, so there’s no specific target or outcome to predict. Instead, the model tries to find hidden patterns or groupings within the data, making it ideal for exploratory analysis.

Examples of Unsupervised Learning

1. Grouping Chemical Compounds

Suppose we want to classify chemical compounds based on their properties like boiling point, density, and solubility. We don’t have predefined labels. Therefore, we can use unsupervised learning. This method finds clusters or groups of compounds with similar properties. This approach helps identify natural groupings, which can inform decisions on material selection or process adjustments.

2. Identifying Catalyst Types

Catalysts can be categorized based on attributes such as activity, stability, and selectivity. By applying an unsupervised learning algorithm, we can identify different clusters of catalysts without needing prior labeling. This process helps to streamline the search for suitable catalysts in specific reactions.

Unsupervised learning is invaluable when analyzing large datasets. It applies to chemical engineering and machine learning. This approach enables engineers to identify hidden relationships that aren’t immediately apparent.

Reinforcement Learning

Reinforcement learning (RL) differs significantly from supervised and unsupervised learning. An RL agent does not learn from a fixed dataset. It interacts with its environment. The agent receives feedback in the form of rewards or penalties. This learning type is ideal for optimization tasks where real-time decisions are required.

Examples of Reinforcement Learning

1. Optimizing Reactor Conditions

Reinforcement learning is particularly useful in process control, where conditions must be adjusted continuously to optimize outcomes. An RL model can manage reactor conditions. It does this by altering variables like temperature and pressure in real-time. This helps to maximize product yield. The model learns from its actions, receiving rewards (high yield) or penalties (low yield) and refining its approach over time.

Through constant interaction with the environment, the model gradually learns the most efficient settings, significantly enhancing the reactor’s overall productivity.

Choosing the Right Machine Learning Type

Each type of Machine Learning in Chemical Engineering serves distinct purposes, as summarized below:

| Learning Type | Best For | Example |

| Supervised Learning | Predicting known outcomes based on labeled data | Product concentration prediction, corrosion rate prediction |

| Unsupervised Learning | Identifying patterns in unlabeled data | Grouping chemical compounds, identifying catalyst clusters |

| Reinforcement Learning | Optimization tasks with real-time feedback | Reactor condition optimization |

Summary: Machine Learning Applications in Chemical Engineering

Machine learning’s adaptability and efficiency make it indispensable in chemical engineering and machine learning integration. It enhances the ability to predict, classify, and optimize processes. Understanding the right type of learning for each scenario is key to maximizing the benefits of ML in this field. ML is transforming the way chemical engineers solve complex problems. It predicts product concentrations and optimizes reactor conditions. New avenues for innovation and improvement are opening up.

By mastering these machine learning techniques, chemical engineers can drive continuous process improvements, achieving greater precision and efficiency.

Read Also:

Future Trends in Chemical Engineering: What You Need to Know in 2024

You must be logged in to post a comment.